Key Differentiators

The Plexus approach to delivering full-service manufacturing excellence

Accelerated time-to-market

Our integrated teams and processes are designed to reduce your product’s journey from initial concept to market launch. We eliminate delays, letting you capitalize on market opportunities faster and gain a competitive edge.

Delivering quality and reliability

We implement quality control measures and continuous improvement methodologies across design, manufacturing and aftermarket services. This holistic approach minimizes risks and ensures the consistent performance your brand depends on.

Optimized total cost of ownership

We’ve engineered our solutions to optimize your total cost, not just unit price. By centralizing oversight and expertise, we can reduce overhead, streamline your supply chain and find efficiencies across the entire product life cycle to deliver greater value.

capabilities

Our end-to-end manufacturing capabilities

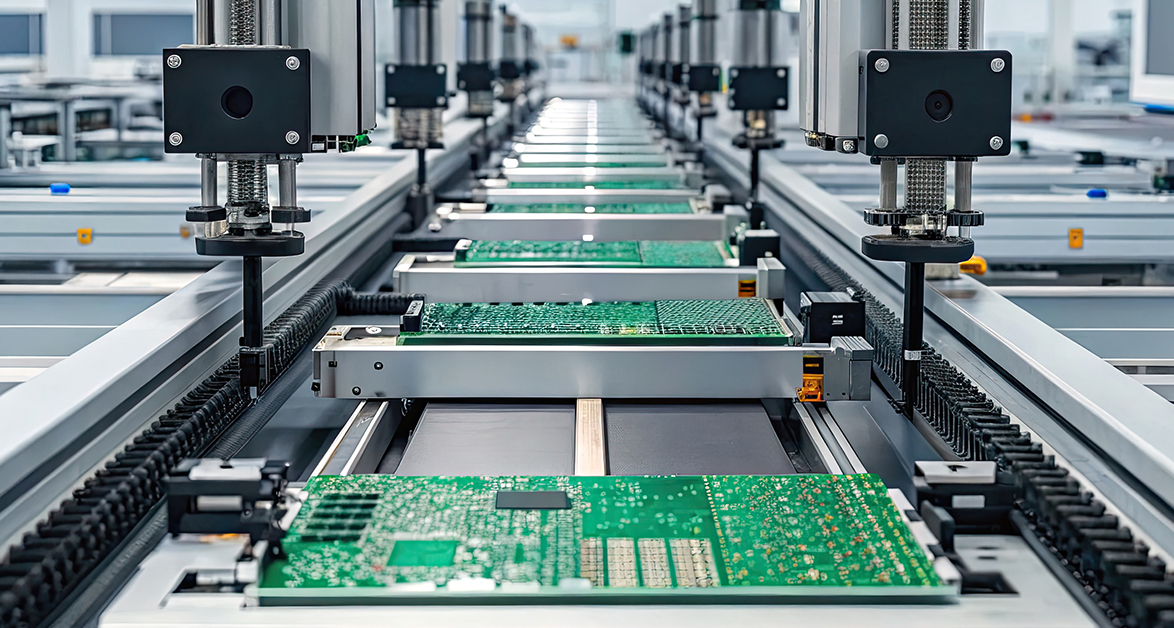

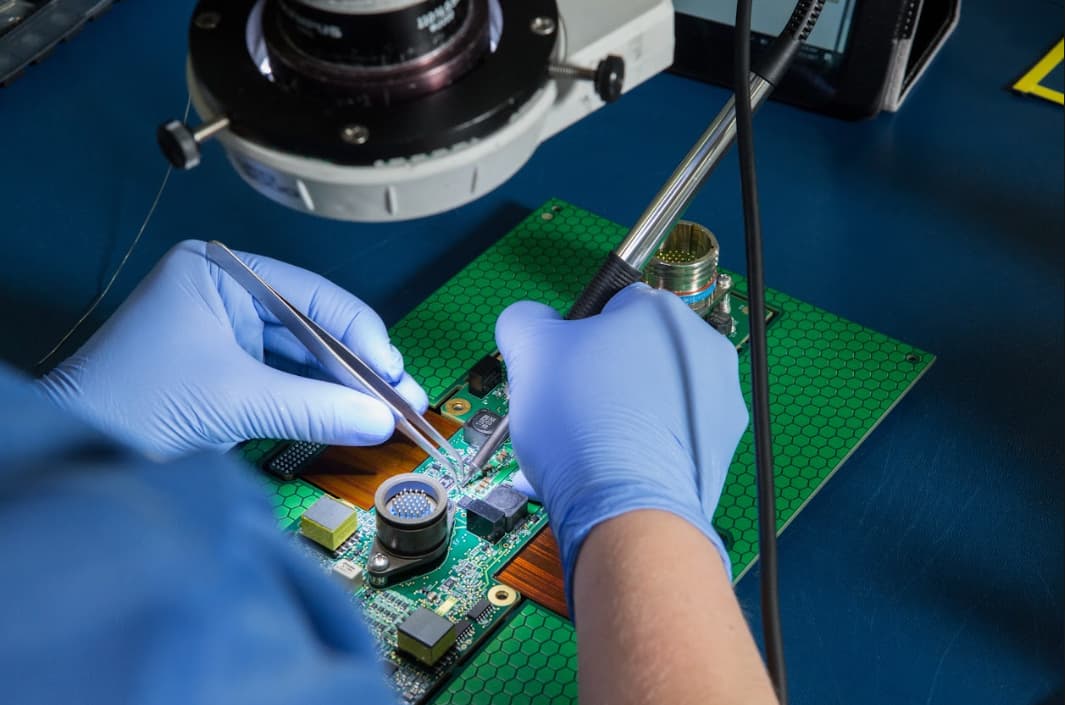

Printed Circuit Board (PCB) Assembly

From high-volume Surface Mount Technology (SMT) with advanced reflow options to compliant RoHS wave soldering, we deliver precise and robust PCB assemblies. We also specialize in advanced PCB designs, including complex multi-layer, Flex and Rigid Flex boards for high-density and versatile applications.

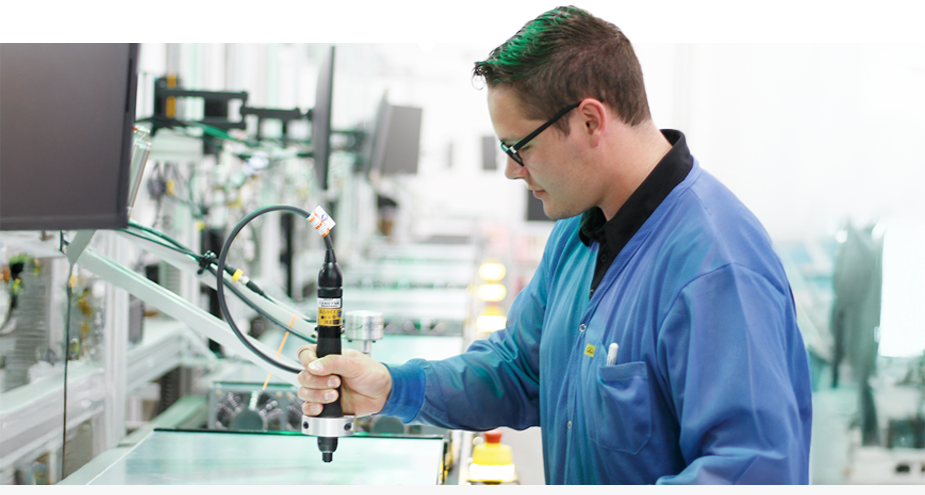

Advanced Assembly & Automation

Our expertise extends to innovative assembly techniques, from press-fit technology for reliable, solder-free connections to the integration of final products through High-Level Assembly (HLA). We also utilize robotics and smart stations with integrated tools like torque drivers and vision cameras to enhance precision, efficiency and quality in every assembly process.

Environmental Protection & Ruggedization

To ensure product durability and reliability in challenging environments, we offer comprehensive protective solutions, including various conformal coatings (Acrylic, Urethane, Epoxy, Silicone) and potting services for robust encapsulation against shock, vibration, moisture and extreme temperatures.