Key Differentiators

Unlocking product quality with the Plexus approach

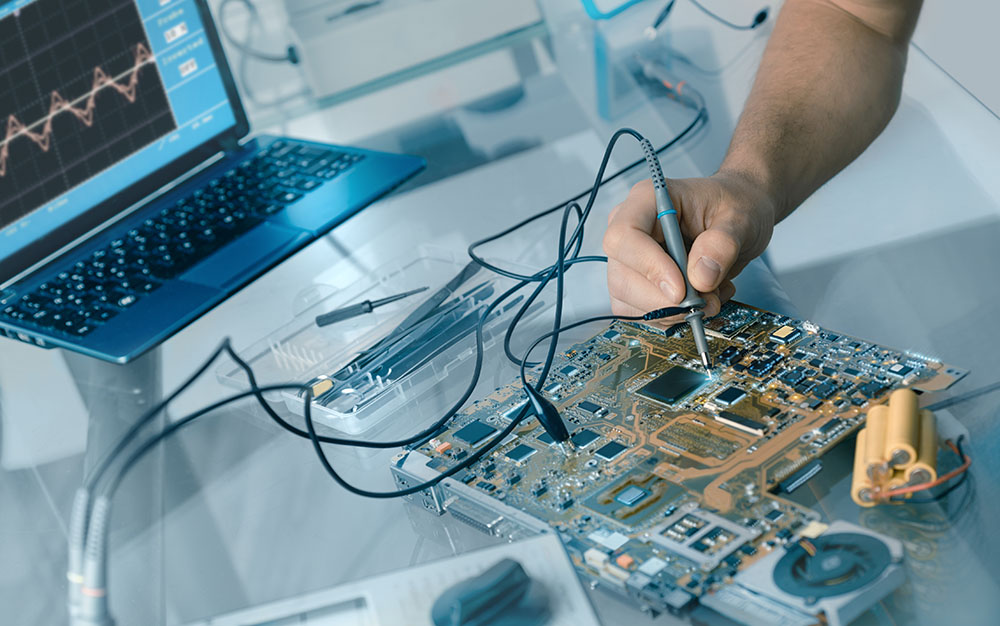

Leveraging advanced testing capabilities

We use cutting-edge technologies like X-ray, in-circuit and functional testing to thoroughly scrutinize your product, Our comprehensive capabilities ensure unparalleled defect detection and a complete understanding of its performance and durability.

Delivering data-driven insights for continuous improvement

Our testing collects and analyzes critical data, providing actionable insights that optimize processes and predict future performance. This approach drives continuous quality improvement and greater efficiency throughout your product’s life cycle.

Assured compliance and risk mitigation

Our integrated processes are built on a foundation of rigorous compliance, ensuring your product meets stringent industry standards. We proactively mitigate potential quality risks, safeguarding your reputation and accelerating market acceptance.

capabilities

Our integrated test and inspection capabilities

Inspection Services

We visually and structurally inspect products to detect defects early, ensuring the highest quality standards before further processing. This includes non-destructive X-ray inspection for complex components with hidden connections, as well as automated vision systems that precisely verify physical attributes like component placement and polarity.

Functional and Electrical Testing

We verify the electrical integrity and operational functionality of your product to ensure it performs exactly as designed. Our comprehensive methods range from in-circuit testing to check component values and connections, to flexible flying probe technology, and full functional testing that simulates the product’s final operating environment.

Reliability and Failure Analysis

Our services are designed to improve product durability and provide critical insights into performance issues. We use Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) to subject products to extreme stresses and uncover weaknesses, significantly enhancing long-term reliability. When failures do occur, our dedicated failure analysis lab investigates the root cause, providing valuable data for continuous improvement.

Quality and Traceability Management

We provide the data management tools necessary to ensure accountability and control throughout the entire manufacturing process. Our end-to-end traceability tracks every component, process and test result from procurement to final shipment, creating a comprehensive data trail for quality control and swift action.