Solution Spotlight

Customer

Solutions

- Design and Development

- |

- Manufacturing

- |

- New Product Introduction

- |

- Supply Chain Solutions

Product

Markets

- Aerospace / Defense

Creating cost efficiency for the next generation of aircraft lighting.

Honeywell Aerospace came to us with a challenge: create the next generation of LED aircraft lighting for the most efficient jet in the sky. See how Plexus hit the product’s aggressive timeline, drastically reduced costs and earned Honeywell’s recognition as Supplier of the Year.

When it comes to more efficient air travel, every detail matters.

The Boeing 777X is designed to be “the largest and most efficient twin-engine jet in the world, unmatched in every aspect of performance.” That’s a high bar. From fuel-efficient engines and carbon fiber wings, to interior comforts, new lighting and more cabin space, everything about the aircraft is intended to create a better way to fly. For Honeywell Aerospace, that meant developing an exterior lighting system that added to both the experience and the efficiency of this impressive new airframe.

So Honeywell came to Plexus for help creating the next generation of LED lighting, with reduced power consumption, longer life and higher output. But it had to happen under a tight timeline and a very aggressive cost target. With Honeywell, we were building a solution for the world’s most efficient plane. And we’d have to do it with the world’s most efficient process.

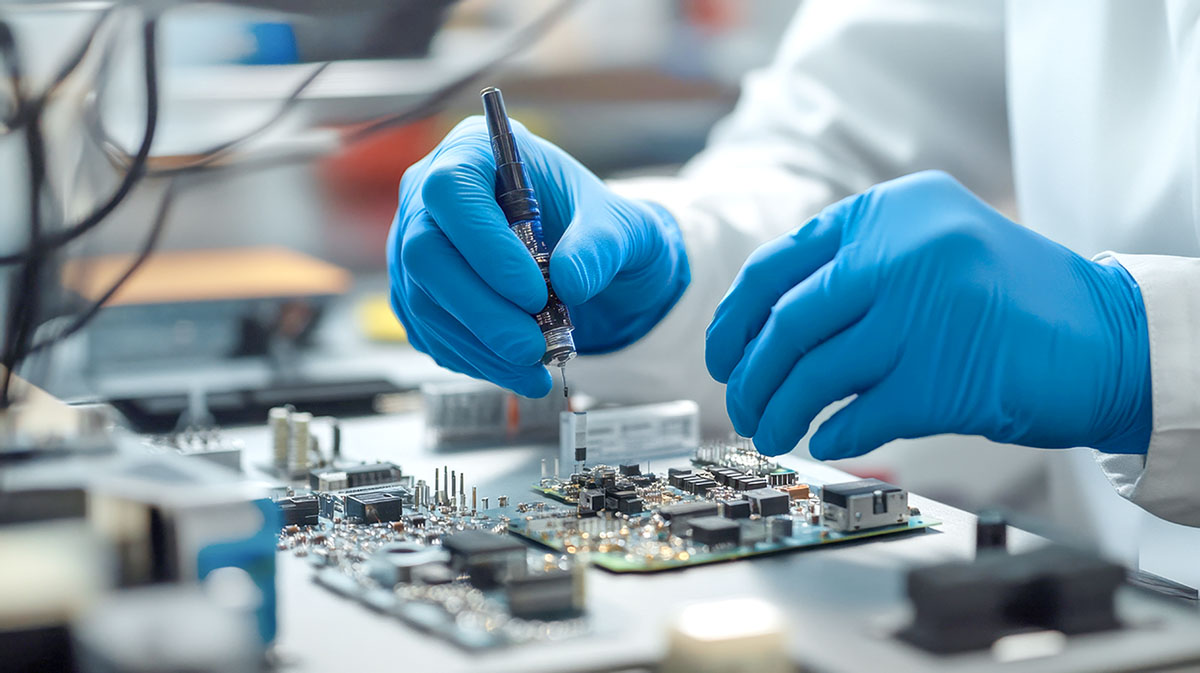

The lighting system had to maintain high performance in harsh conditions, which required an IPC Class 3 circuit board assembly at an AS9100 quality level.

Collaborating from the start.

To meet the product’s cost and timeline demands, Honeywell knew they’d need Plexus to be involved from the earliest stages. So they brought us in as part of their Early Supplier Engagement process. Our team felt right at home with this level of upfront collaboration — it’s the same kind of integration we’ve built our own product realization process to achieve.

Early supplier engagement allowed us to work closely with the Honeywell team to validate the product design, identify any challenges and address them upfront. Our Design and Development, New Product Introduction, Manufacturing and Supply Chain teams were able to analyze project needs and get started on finding solutions right away. And we could accelerate the process with 24-hour project support thanks to seamless integration between our North American and Malaysian engineering and manufacturing resources.

Finding efficiencies at every stage.

Meeting the customer’s very aggressive cost target meant finding every opportunity to remove cost from the product. As part of our design for excellence process, we were able to use design for fabrication to pinpoint the biggest cost drivers and engineer solutions that would reduce cost in those specific areas.

The highly compressed timeline for evaluation and qualification builds required rapid sourcing of components and high-level, integrated program management. Our program managers and supply chain experts worked to intelligently source lower-cost components and identify parts that we could order immediately to compress the timeline. The team analyzed all needs upfront to identify any time or cost risks on the supplier side, then located alternate suppliers if necessary. Supply chain worked to minimize any reliance on single sources and bring together multiple suppliers for the greatest efficiency.

Rapid prototyping also played a major role in both speeding up the process and cutting costs. Our team was able to quickly procure parts and assemble the product for evaluation. Then we could find any concerns, communicate them directly with the Honeywell team and resolve them immediately.

Throughout the process, constant communication with the Honeywell team was key to keeping all of these moving parts on track. We listened carefully to the customer’s needs at every stage with regular face-to-face meetings. Our teams held on-site kaizen meetings to ensure continuous improvement, while integrated product development team meetings happened at least weekly. And consistent problem-solving sessions helped us identify any risks to project milestones, discuss them with the Honeywell team and find solutions long before issues could arise.

The design for excellence process helped us remove more than 30 percent of the originally estimated cost from the product.

Creating our part of a better flying experience.

Honeywell Aerospace has been more than satisfied with the results of their collaboration with Plexus. Based on our performance in meeting the project’s aggressive cost and timeline requirements, Honeywell awarded us as their 2016 New Product Development Supplier of the Year.

The new LED lighting system not only supports Boeing’s competitive strategy, but it will make a direct impact on the 777X experience as a whole. As exterior lighting meant for communication during approach and takeoff, the system is integral to passenger safety. Lower power consumption adds to the plane’s higher fuel efficiency, which can translate to cost savings in airfare. The reduced energy demand also means more power available for passenger comforts like in-flight connectivity and entertainment. And the product’s longer life allows for less maintenance, less downtime and fewer flight delays.

Out of 150 suppliers, Honeywell Aerospace selected Plexus to receive the 2016 New Product Development Supplier of the Year award.