Five Steps to Circular Manufacturing & Zero Waste

In today’s rapidly evolving industrial landscape, the traditional linear model of ‘take-make-dispose’ is proving unsustainable, leading to soaring resource consumption, escalating waste volumes and unpredictable raw material markets. For forward-thinking manufacturers, embracing circular manufacturing strategies isn’t just an environmental imperative; it’s a strategic necessity that unlocks greater resilience, efficiency and independence.

The European Union’s Clean Industrial Deal (CID), introduced in February 2025, underscores this shift, signaling that resource conservation, circularity and industrial competitiveness must advance hand-in-hand. Without this fundamental change, global waste generation could increase by two-thirds by 2050. The transformation toward a resource-efficient industry is no longer just a climate policy objective, but a crucial driver of long-term viability.

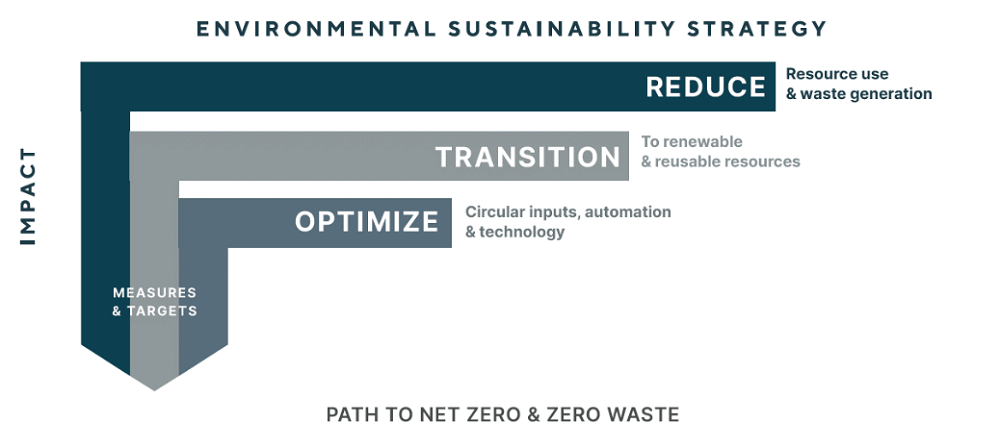

As companies increasingly prioritize climate neutrality, with one in five manufacturers aiming to achieve it within the next decade, the challenge of closing material loops and systematically reducing waste becomes paramount. This makes zero-waste strategies central to future-ready manufacturing, a commitment deeply embedded in Plexus’ operations and a key part of our sustainability efforts.

Laying the Foundation for Sustainable Action

Here at Plexus, we take a holistic, globally coordinated approach to systematically reduce waste and make environmental goals measurable. The foundation is the Environmental, Health and Safety Management System (EHSMS), applied across all our sites worldwide. It defines binding standards for environmental, health, and safety processes, and ensures that sustainability goals are consistently embedded into operational routines. A standardized Site Management System (SMS) supports this by driving site-specific improvements through data-based decision-making.

Plexus aims to avoid waste at the earliest possible stage of the product realization, starting with design and continuing through product development. This includes sustainable electronics manufacturing strategies such as resource-efficient product development and optimized manufacturing processes. In practice, however, completely avoiding all waste is not always immediately feasible. This is where the principle of “Zero Waste to Landfill” comes in. The goal is to divert as much waste as possible from landfills, instead recovering it through material recycling, energy use, or raw material recovery. We demonstrate how this works in practice through five concrete areas of action.

1. Data-Driven Waste Management

Effective waste reduction hinges on transparent, actionable data regarding quantities, material streams and disposal methods. Only when it is clear where, how much and what type of waste is being generated can well-founded decisions be made and progress reliably tracked. In complex industrial manufacturing environments, where diverse materials and processes are intricately intertwined, digital tools for data collection and analysis are paramount.

Plexus leverages a centralized waste data tracking system to meticulously monitor, analyze and control all waste streams across our global operations. Through close collaboration with our waste management partners, we receive comprehensive data via legally required Waste Transfer Notes, confirming each waste handover. Our Environmental, Health and Safety Management System (EHSMS) team diligently collects and categorizes this monthly data, from mixed waste to recyclables and hazardous materials, ensuring each type is managed in the most environmentally responsible way. To uphold data integrity, our team also conducts rigorous internal spot checks.

At the Kelso (Scotland) manufacturing site, the responsible teams identified an unexpectedly high volume of solder waste based on waste tracking data. This led to an internal review of storage and shelf-life processes and the adjustment of FIFO (First In, First Out) controls to minimize material losses. Thanks to these waste reduction strategies, Kelso was able to recycle approximately ninety-three percent of its waste in the past fiscal year, with the remaining seven percent being used for energy recovery. At the Oradea site in Romania, only five percent of waste is sent to landfill, while eighty-six percent is recycled.

2. Recycling and Internal Recovery

Recycling reintegrates materials into the production cycle, reduces the need for virgin resources and makes a significant contribution to resource conservation. In sustainable electronics manufacturing particularly – with its complex, often hard-to-separate material compositions and critical raw materials – high-purity recycling plays a key role. Only cleanly separated streams enable the recovery of valuable resources, from precious metals to rare earth elements. This makes it all the more important to organize material recovery through clearly defined processes and reliable partner networks.

Achieving this level of recovery demands a functioning ecosystem where all stakeholders collaborate with clear responsibilities, from collection and sorting to processing and reintegration into the value chain. Plexus actively serves as a coordinating element, ensuring all parties along the value chain align towards shared sustainability goals.

For comprehensive WEEE (Waste Electrical and Electronic Equipment) management, Plexus collaborates with licensed AATF (Approved Authorised Treatment Facility) partners, such as the one in Normanton, UK. Here, teams meticulously inspect used electrical and electronic equipment, preparing items for direct reuse on the UK market or carefully dismantling them for high-purity material recovery and recycling. For portable battery recycling, Plexus partners with specialist recycling plants, including a facility in Halifax, Canada. After initial sorting, alkaline batteries are shredded and passed through induced magnetic separators to efficiently recover precious metals like nickel, copper, and zinc oxide. Recovered nickel can be repurposed for items such as cutlery, copper for electronic components and zinc oxide for household white paint. Any leftover materials like carbon, plastic, or paper are removed for further recycling. The company also applies specialized separation methods for materials from toner cartridges, ink cartridges, and fluorescent lighting tubes. This enables Plexus, through its expert network, to reintegrate materials such as steel, glass, or mercury into new products, ranging from household appliances to road construction.

3. Packaging Management and Material Use

Packaging represents one of the most significant sources of avoidable waste within industrial supply chains. With Germany alone generating 19.2 million metric tons in 2021, the immense potential for reduction is clear. Recognizing this challenge, the EU’s new Packaging and Packaging Waste Regulation (PPWR), effective February 2025, sets stringent requirements for the design, recyclability and reuse of industrial packaging. This regulation aims to establish a standardized EU packaging market with clear guidelines across the entire lifecycle, from production to usage to recovery.

At the Plexus site in Kelso, cardboard constitutes the largest share of our packaging waste. While often perceived as eco-friendly due to its renewable origin, paper-based packaging production still demands substantial amounts of water, energy and chemicals.

To reduce cardboard packaging waste, Plexus applies a combination of reuse, redesign and modularization, key circular manufacturing strategies. Wherever possible, we modify incoming packaging to enable its reuse for shipping finished products. Furthermore, we actively collaborate with our customers to develop innovative packaging concepts that not only reduce material consumption but also optimize transport volume.

4. Building Internal Awareness

Effective waste prevention thrives when structured actions are seamlessly integrated with a culture of shared responsibility. Even the most advanced waste management system is ineffective unless deeply embedded into daily routines, from the factory floor to the cafeteria.

Plexus has cultivated this crucial internal awareness through a comprehensive suite of initiatives. Our cross-site EHSMS teams continuously analyze workplace behavior, monitor progress, and adapt measures to foster ongoing improvement. Practical tools like color-coded collection bins, clearly illustrated instructions and well-marked sorting stations provide clear guidance for all employees. Beyond these tools, we prioritize raising awareness among new team members during onboarding and deepen existing employees’ knowledge through ongoing training campaigns and informational programs. Complementary practical actions, such as dedicated e-recycling days and the removal of single-use plastics in canteens and customer areas, reinforce our commitment. These are all part of our sustainability efforts to empower our workforce.

5. Material and Energy Recovery

Material and energy recovery represent the crucial final stage of the waste hierarchy. This approach is applied when reuse or recycling is not technically or safely feasible, offering a meaningful and legally regulated alternative to landfilling. Modern high-temperature incineration systems efficiently reduce the solid mass of waste by over eighty percent and its volume by up to ninety-five percent, while simultaneously generating usable energy.

Plexus leverages this approach through strategic partnerships, such as with a high-temperature incinerator facility in East Kent, England. This site is one of only four such plants in the UK fully permitted to incinerate even the most hazardous waste streams, including clinical, flammable, explosive, oxidizing, and infectious waste, as well as safety-critical components from the defense and aerospace sectors. The heat and energy produced during this incineration process are harnessed, classifying this as a recovery process within the waste hierarchy. All operations comply with legal regulations and are fully documented through Certificates of Destruction. A dedicated 26-person team operates the system around the clock in shifts, maintaining, monitoring and continuously optimizing the facility. This thermal recovery significantly reduces landfill volumes, making it a key pillar of Plexus’ Zero Waste to Landfill strategy, and contributes to our comprehensive circular manufacturing strategies.

Achieving zero waste is not a singular goal, but an ongoing journey of continuous improvement that thrives on collaboration. As an EMS provider, Plexus extends its responsibility beyond internal operations, acting as a crucial connector within a comprehensive ecosystem of recycling partners, waste management services and technology experts. This integrated network empowers our customers to pursue their zero-waste ambitions not in isolation, but as part of a connected value chain, fostering more sustainable, transparent and resilient operations.

Partner with Plexus to Advance Your Circular Manufacturing Journey

Building a truly circular manufacturing model can be a transformative step, driving significant environmental benefits and long-term business value. By collaborating with an experienced EMS provider like Plexus, you gain a decisive advantage. We enable your journey through data-driven waste management, advanced material recovery and integrated solutions that empower your teams to focus on core innovation while building a more sustainable future.

Contact Plexus

Contact Plexus today to discuss how our expertise in circular manufacturing can support and accelerate your sustainability strategy, propelling your business towards predictable growth and enhanced environmental stewardship.