Solution Spotlight

Customer

Solutions

- Design and Development

- |

- Manufacturing

- |

- New Product Introduction

- |

- Supply Chain Services

Product

Markets

- Industrial

An integrated solution to scale global demand, ensure customer’s NEVI compliance and drive power electronics innovation.

Summary

A leading European provider of high-tech power electronic systems chose Plexus as an integrated Electronic Manufacturing Services (EMS) partner to secure its global growth trajectory. Facing a critical need to scale its EV charging products while complying with complex regional regulations like the U.S. National Electric Vehicle Infrastructure (NEVI) program, the company required a de-risked and agile solution.

By leveraging Plexus’s integrated global network, the customer gained the necessary capacity, supply chain resilience and trade compliance expertise. This partnership enabled successful expansion into challenging new markets without the burden of costly greenfield investments, allowing the customer to keep its internal resources focused on core technology innovation and customer development.

The Challenge

The company was facing a critical juncture in its growth trajectory. It needed to scale its manufacturing and supply chain significantly to meet its growth targets by 2025 and satisfy global demand for its EV charging products.

A key challenge was the increasing protectionism in new markets like the U.S., which required a manufacturing solution that could comply with regulations such as the NEVI program. Building a greenfield supply chain and manufacturing operation from scratch was a high-risk, expensive and time-consuming option that would have diverted critical management time, capital expenditure and human resources away from their core intellectual property (IP).

The Solution

This challenge required an agile solution for the industrialization of complex products at scale. Plexus delivered a scalable, full value stream solution leveraging its integrated global network and deep market expertise. The strategic solution was segmented across two key regions:

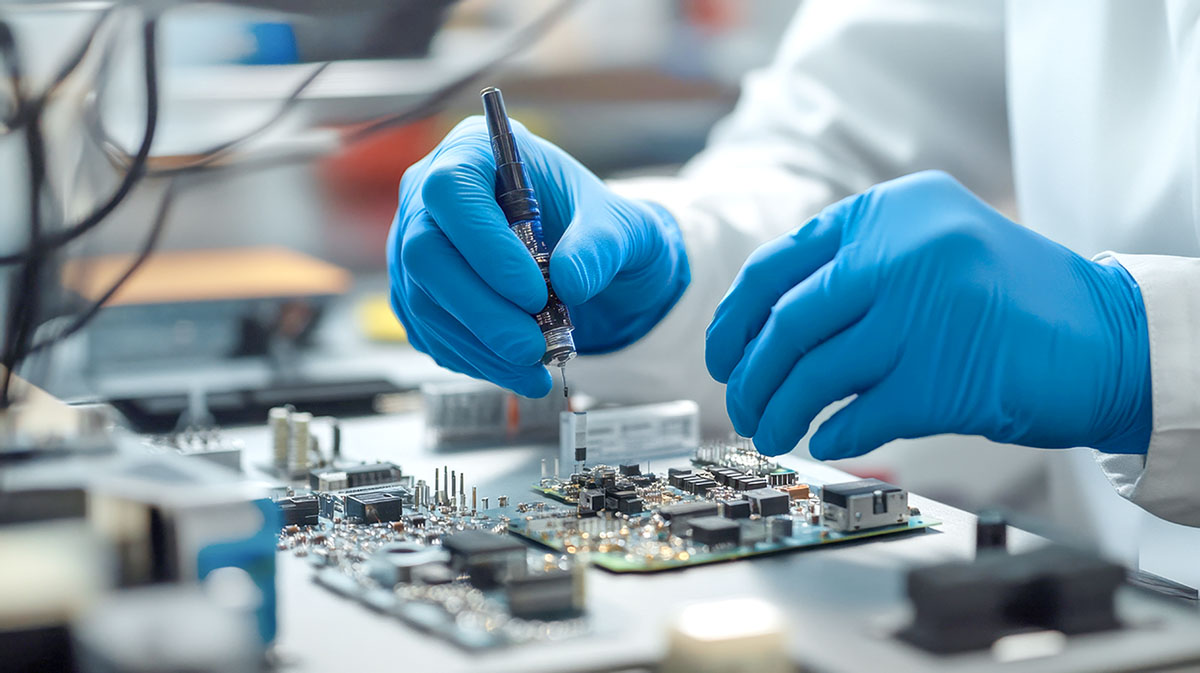

Complex PCBA Manufacturing in Europe

The foundational step for scaling this global program was establishing Printed Circuit Board Assembly (PCBA), the brain of the EV charging unit, at Plexus’s Oradea, Romania, facility. This strategic positioning provided the customer with low-cost manufacturing, close proximity to their European headquarters and essential time-zone alignment for efficient supply chain management.

To industrialize a double digit quantity of different, highly complex PCBA designs, secure components in a constrained supply market and support the significant ramp-up volume in a short period of time, Plexus deployed significant resources to make the customer successful.

Oradea successfully delivered over 200,000 units during the critical ramp period (April 2023 through May 2024), achieving the consistent quality and scale necessary to industrialize this highly complex product.

High Level Assembly in the United States

To support our customer’s opportunity to expand into the US market, Plexus rapidly established manufacturing in the Appleton, WI facility along with a scalable localized supply chain. This site is entirely dedicated to complex, high-level assembly (HLA) for industrial market sector customers. This strategic placement was key to supporting our customer’s success in the U.S. market, meeting the customer’s NEVI compliance and ‘Made in the U.S.’ requirements, enabling significant cost savings on freight and increasing flexibility due to market proximity.

In addition to location, Plexus was able to improve our customer’s manufacturing efficiency through technology and processes. A key feature of the line are workstations enabled with smart torque drivers to measure and control the precise rotational force applied to each screw in a subassembly.

Plexus also implemented visual inspection for several subassembly steps. This process improvement digitally reviews various subassemblies against a gold standard image to ensure the components meet quality standards. Both of these steps drove greater repeatability and automation, improving overall quality and reducing production attrition.

Given that the customer’s product stands approximately 2.2 m (7.2 ft) tall and weighs up to 890 kgs (1,962 lbs), Plexus needed to implement ergonomic steps to ensure safety for team members and efficiency in production. To move the product through assembly, we designed a custom conveyor belt system. As the product moves along the conveyor, the entire system raises and lowers to adjust for different heights to meet ergonomic standards. We also installed auto-lifters to lift and insert various subassemblies weighing up to 110 kgs (243 lbs).

Plexus partnered with the customer to integrate their test fixtures into our facility, applying our experience in high-power functional test and ensuring our facility could sustainably handle the immense power load for each test run. Under high load testing, the test system receives 200kW of DC electricity. The system recycles that power by converting it back to 480VAC and feeding it into the product, consuming only the energy that the equipment dissipates as heat.

Strategic Benefits of the Partnership

This full product life cycle partnership with Plexus provided four key benefits, enabling the customer to secure global leadership in EV charging solutions:

- De-risked Market Entry and Compliance: Plexus provided the required trade compliance expertise, recommending a supply chain solution designed to successfully address the customer’s stringent NEVI requirements.

- Avoid CAPEX Manufacturing Investment: The partnership allowed the customer to leverage Plexus’s significant balance sheet and operational strength to maximize its growth and financial performance, minimizing risk and optimizing profitability by not incurring the costly CAPEX of establishing its own manufacturing facility.

- Engineering and Design for Excellence Support: Co-located Plexus engineering teams provided immediate value-added services such as Design for Manufacturability (DFM) analysis and DFX support to reduce cost, improve manufacturability and optimize test strategies from the earliest stages of design.

- Transition Team: Plexus deployed a dedicated transition manager and a proven New Product Introduction (NPI) process to transfer and ramp up manufacturing.

The Results

By partnering with Plexus, the customer achieved a scalable, flexible manufacturing solution that secured the necessary capacity, speed and agility to support its ambitious growth forecast. The outcome enabled the customer to meet all requirements for compliance for EV charging while achieving industrial OEM scale.