Solution Spotlight

Customer

Solutions

- Design and Development

- |

- Sustaining Services

Product

Markets

- Healthcare / Life Sciences

Summary

A global medical device manufacturer partnered with Plexus to develop a sustainable and efficient packaging solution for electronic circuit boards used in highly sensitive devices like MRI, CT and ultrasound systems. The collaboration resulted in a new, robust and recyclable tray-based packaging that significantly reduced transport damage, cut costs and improved supply chain efficiency. The project demonstrates that sustainable packaging can also lead to substantial operational benefits and a competitive advantage.

The Challenge

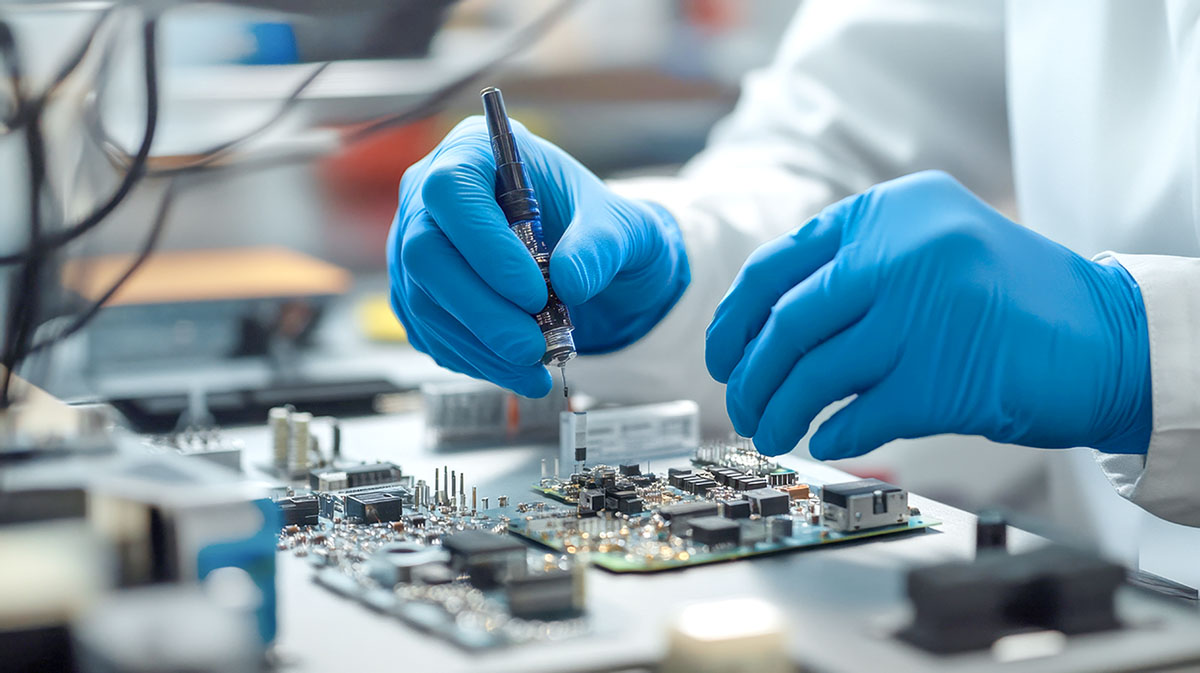

The medical technology sector is undergoing a major shift, driven by new regulations, rising costs and the need for sustainability. As a result, the medtech packaging industry is under pressure to adapt to these changes. A global medical device manufacturer faced several challenges with its original packaging for sensitive electronic circuit boards. The original packaging was not only cumbersome, but it also contributed to the risk of transport damage, which in turn increased scrap and replacement costs.

Furthermore, the inefficient design wasted valuable storage space and led to higher logistics and operating costs because the original packaging not only required more packaging materials but also necessitated larger shipping containers for fewer circuit boards per container, thereby requiring more total shipments. The manufacturer’s use of single-use plastic bags also meant high material consumption and significant transport-related emissions. This situation highlighted the urgent need for a more sustainable packaging solution to address the environmental impact of non-clinical waste (i.e., scrap circuit boards, single-use bags and packaging materials) generated by the supply chain.

The Plexus Approach: Engineering for Triple Impact

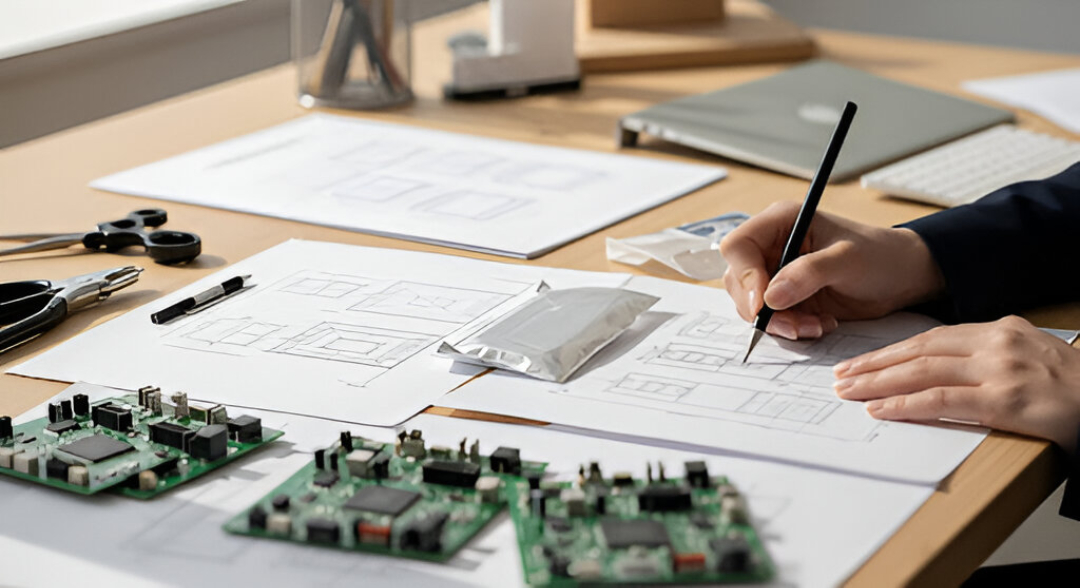

As a full-service EMS Partner, Plexus recognized that the solution lay in applying Design for Sustainability principles directly to the packaging engineering. Our team didn’t just look at material replacement; they focused on a total supply chain overhaul to maximize efficiency, which is a key component of true sustainability. This approach ensured that the operational benefits of sustainable packaging were realized immediately.

The engineering team collaborated closely with the customer’s supply chain and quality departments to create an optimized solution, making the final design robust and user-friendly. The goal was not only to protect the sensitive electronics but to also achieve medical device cost reduction through efficiency.

The resulting design was a robust, user-friendly and recyclable plastic tray that was engineered to efficiently accommodate nearly thirty different circuit board configurations. Crucially, this new tray design allowed for an increase in the number of boards shipped per delivery by up to 33% compared to the original packaging method.

The optimized tray system significantly reduced the risk of transport damage, reinforcing the product’s safety and functionality. The design also improved efficiency by optimizing storage space on the production line and significantly enhancing packing density. Furthermore, a revised labeling system was incorporated, making inventory scanning and counting easier, which led to faster storage processes and fewer stock discrepancies. By replacing single-use plastic bags with this new recyclable tray and enabling a smaller outer shipping container, Plexus reduced overall material consumption. This new solution created a “win-win” situation, contributing to a cost reduction of nearly 50% compared to the original system. Our solution delivered true packaging optimization for both cost and ecological impact.

The Results

The new packaging solution provided significant benefits, demonstrating that sustainability and operational efficiency can go hand-in-hand. Our focus on improving supply chain efficiency in medtech delivered quantifiable success:

By partnering with Plexus, the manufacturer was able to create a packaging solution that met ecological, functional and regulatory requirements, giving them a significant market advantage.

Contact Plexus

Contact us today to discuss your packaging optimization and sustainability goals.