- Moving a new in vitro diagnostic (IVD) technology to market.

- Getting the details right.

- Building the solution

- Printed Circuit Board Assembly (PCBA) reviews.

- Design improvements for safety.

- Design improvements for user experience and perceived quality.

- Design for performance and cost.

- Manufacturing methods review for quality and cost.

- Bringing a complex MDx product to market.

Solution Spotlight

Customer

Solutions

- Design and Development

- |

- Manufacturing

- |

- New Product Introduction

- |

- Supply Chain Solutions

Product

Markets

- Healthcare / Life Sciences

Molecular Diagnostic Instrument

Moving a new in vitro diagnostic (IVD) technology to market.

Getting your new molecular diagnostic (MDx) product to market quickly matters not only to you and your shareholders, but to the physicians who will use it – and more importantly, to the patients whose health is at stake.

The customer came to Plexus with a high investment hurdle – to launch and distribute a new molecular diagnostic (MDx) instrument for rapid bacterial detection, identification and antimicrobial susceptibility testing. See how Plexus minimized design and development delays, increased collaboration and helped bring a new IVD technology to market.

Getting the details right.

Before this technology was acquired by a major MDx firm, and before the project came to Plexus, there were two design firms contributing to the instrument design.

As Plexus began to review the existing system design, we uncovered a number of issues that yielded the design incompatible with good manufacturing practice (GMP) standards. The issues included component obsolescence and significant quality and safety issues (e.g., warped instrument enclosure panels, lack of adequate safety shielding, etc.). While this was not a surprise to our customer, it wasn’t acceptable. They needed a partner that could support the instrument development – one committed to providing an exceptional product, aiming to achieve zero defects and quickly transition to manufacturing in order to support their clinical trials and the commercial launch of this new product. Based on Plexus’ thorough review and proposed solutions, including our industry leading expertise in manufacturing many Class I, II and III medical devices, this customer knew that Plexus could support their needs. Our commitment to operational excellence – delivering a quality product, at fair price, consistently across the globe – offered reassurance as they partnered with Plexus to help minimize any further delays in their product launch.

Building the solution

With a definitive course of action, Plexus applied our product realization services to design and develop the product.

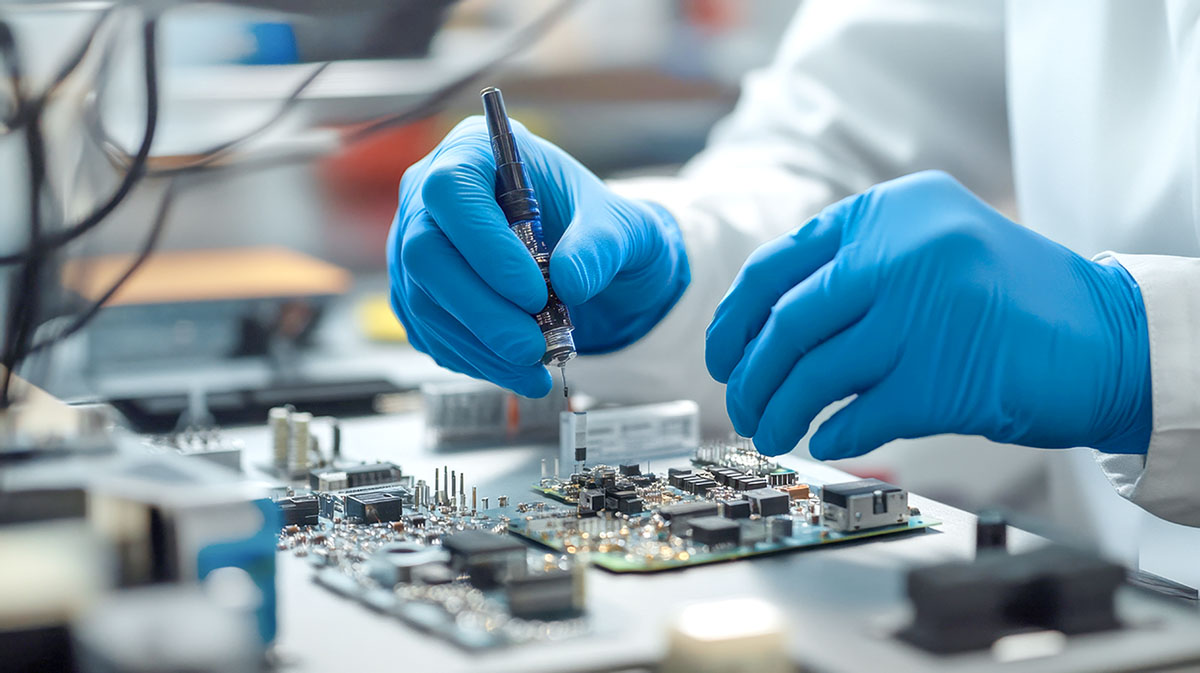

Printed Circuit Board Assembly (PCBA) reviews.

Plexus reviewed and conducted design for excellence (DFX) analyses for 7 PCBAs. This included sourcing alternate components to address several instances where end of life, or obsolescence, issues were found. A thorough review of all PCB and component sources was completed to leverage Plexus’ supply chain risk management and purchasing power, ensuring optimization of costs and guaranteeing continuity of supply for years to come.

Design improvements for safety.

Plexus reviewed the overall instrument assembly from a safety standpoint and then designed and implemented interior covers to isolate electronics and optics components, providing protection from potential exposure to users and service personnel. These covers also served to prevent any potential reagent/waste contact with these instrument sub-systems, which provided additional protection against hazards, potential instrument down time, and made instrument decontamination easier.

Design improvements for user experience and perceived quality.

Several design changes were made to improve the user experience and tactile interface. For example, the access door closing mechanism (feel of handle, noise of closing mechanism, feel of motion/resistance, feel of closure engagement, etc.). Additionally, the overall noise of the instrument was substantially reduced by changing to more efficient internal cooling.

Plexus determined, with customer agreement, that encoders were necessary to meet accuracy and reliability requirements. With extensive experience in robotic encoder integration, Plexus proceeded to make this change quickly to meet performance requirements.

Design for performance and cost.

Review of custom part designs revealed an imbalance between cost and performance. This led to the update of 95 custom parts. In some cases, part specifications were relaxed to reduce production costs while still ensuring delivery of required functionality and performance. In other cases, part specifications were increased to ensure delivery of reliability and precision needs. Overall, cost for the aggregate change in parts was reduced while improving the instrument’s performance and reliability.

The initial robotic motion control system was designed without encoders in order to save cost. Plexus determined, with customer agreement, that encoders were necessary to meet accuracy and reliability requirements. With extensive experience in robotic encoder integration, Plexus proceeded to make this change quickly to meet performance requirements.

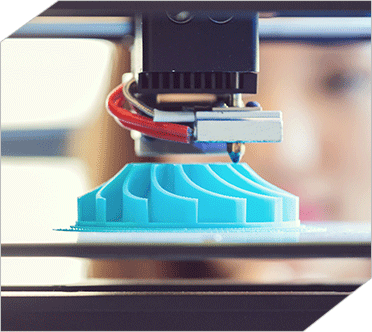

Manufacturing methods review for quality and cost.

Manufacturing methods of many parts were reviewed and adjusted to optimize for quality and cost. This included changing the production method of some parts from machining to injection molding or additive manufacturing. Such changes helped to reduce costs, while still delivering performance and reliability. Likewise, polymer materials used to produce some parts were changed to alter rigidity and durability while reducing costs.

As noted, these reviews and changes not only improved costs, but improved visible quality issues (e.g., instrument enclosure finish quality, perceived fit and finish of user interfaces, etc.).

Bringing a complex MDx product to market.

Following completion of the above reviews and changes, Plexus delivered everything needed – minimized design and development delays, increased collaboration and transitioned the customer’s molecular diagnostic (MDx) instrument into manufacturing successfully. This included all items needed for the design history file (DHF) and version controlled firmware.

Plexus was also able to supply the customer with all documentation needed to support their regulatory filings and built pre-clinical testing units to support their clinical testing schedule. This instrument successfully obtained CE-IVD status and was granted FDA market clearance through the De Novo process.

The technology is currently supporting doctors in their ability to detect early infections, reducing the likelihood of further transmission, as well as proactively informs their determination of which antibiotic regimens will work best to treat each patient.

- Moving a new in vitro diagnostic (IVD) technology to market.

- Getting the details right.

- Building the solution

- Printed Circuit Board Assembly (PCBA) reviews.

- Design improvements for safety.

- Design improvements for user experience and perceived quality.

- Design for performance and cost.

- Manufacturing methods review for quality and cost.

- Bringing a complex MDx product to market.